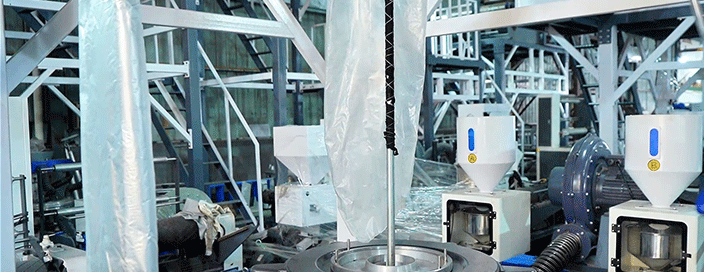

Guoran blown film machines integrate advanced technology and intelligent design to deliver high-performance solutions for all your film production needs, from food packaging and agricultural mulch to industrial and medical films.

✅ Boosted Productivity: Features a 32:1 L/D ratio screw design, increasing output by 20-30% while reducing energy consumption by 15-25%.

✅ Superior Versatility: Capable of processing a wide range of materials including HDPE, LDPE, LLDPE, and biodegradable polymers.

✅ Robust & Reliable: Known for exceptional durability, high output, and stable performance, ensuring consistent quality for various applications.

✅ Complete Model Range: Offers single to multi-layer co-extrusion lines to meet diverse production requirements.