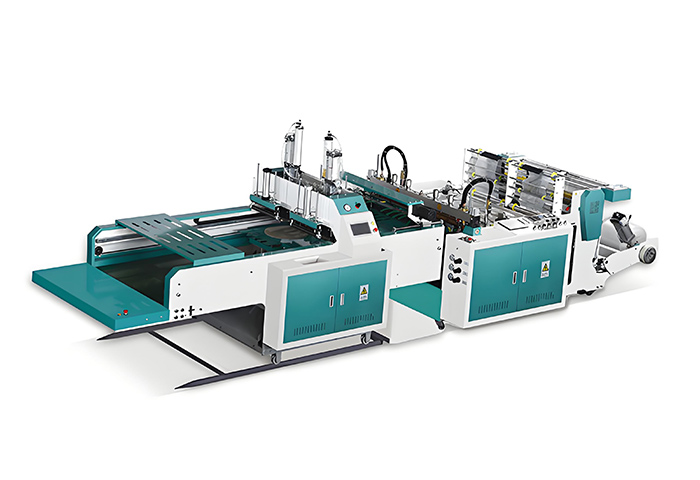

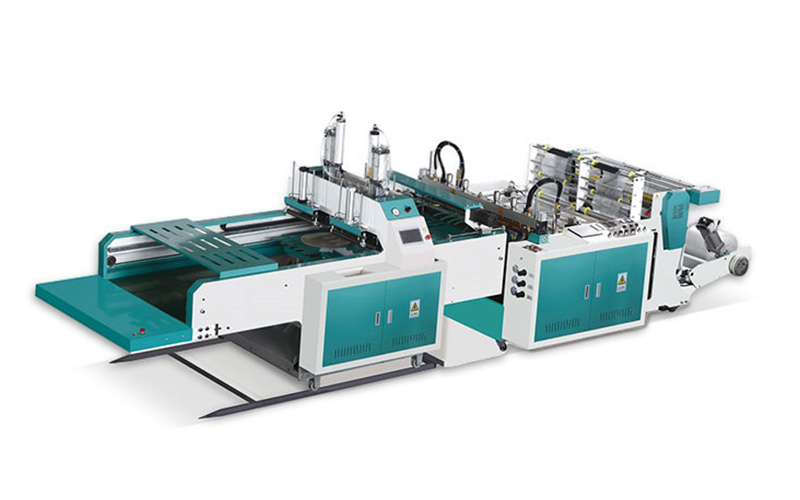

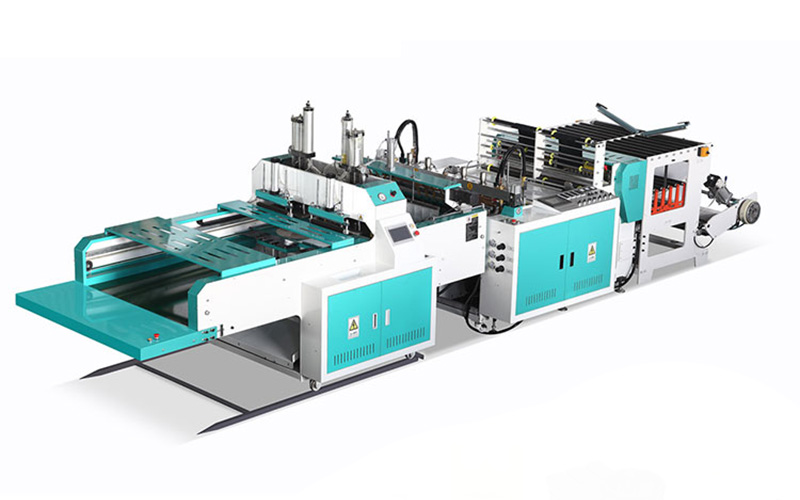

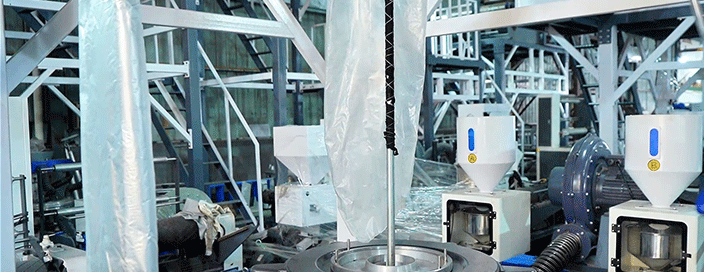

Guoran plastic bag making machines are suitable for processing PE, PP, PLA, and other flexible films into a wide variety of bags through automatic sealing, cutting, and stacking. The machine can be equipped with advanced servo control and photoelectric tracking systems to ensure high precision and stable performance during production.

Guoran plastic bag making machine is known for its high efficiency, reliability, and versatility, making it an ideal choice for food packaging, retail, medical, and industrial applications.

✅ Simple operation: User-friendly interface and automated control system make operation easy to learn, adjust, and maintain.

✅ High versatility: Supports multiple bag types such as T-shirt bags, garbage bags, zip-lock bags, and biodegradable bags.

✅ Stable performance: Servo-driven feeding and tension control ensure accurate sealing and cutting for consistent bag quality.

✅ Energy saving: Optimized heating and motion systems reduce power consumption while maintaining high output.

✅ Customizable options: Available with GT-A1300 Horizontal Slitting Machine, JL-8T Hydraulic Punching Machine, Auto Loader, etc,.