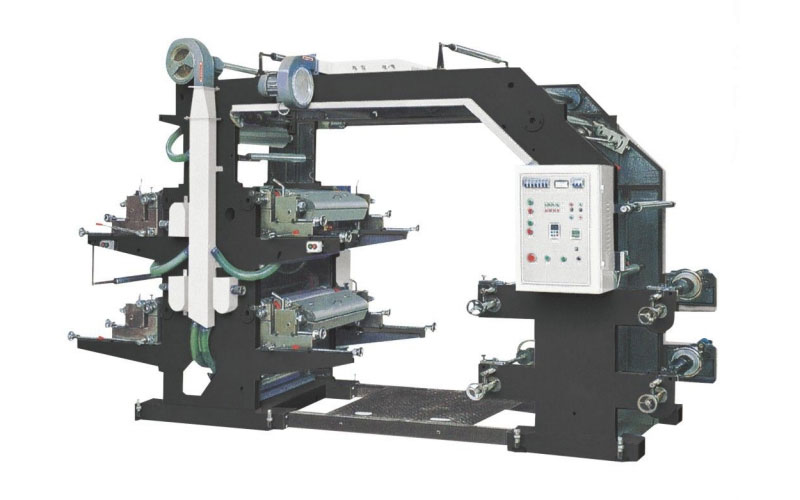

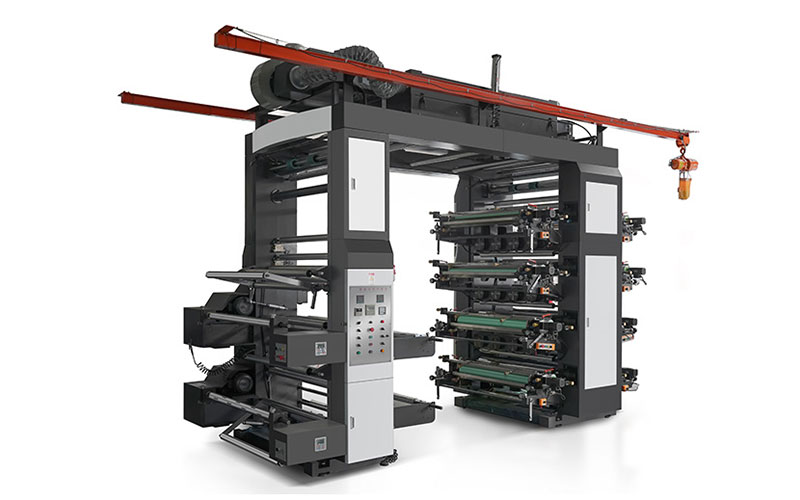

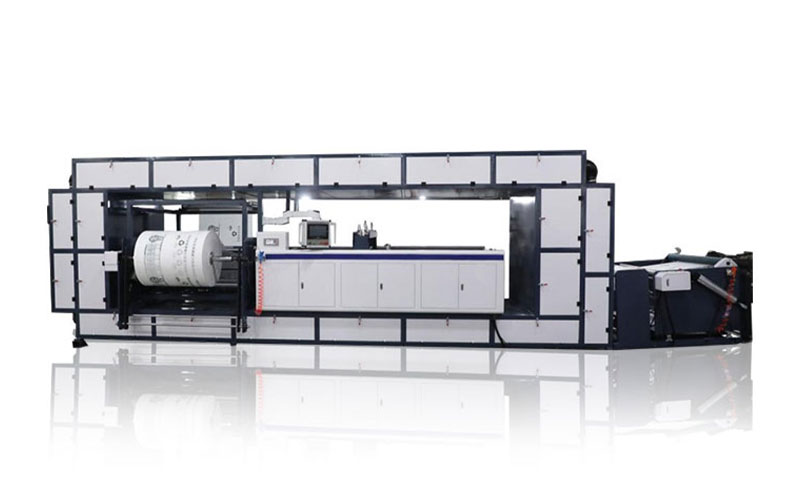

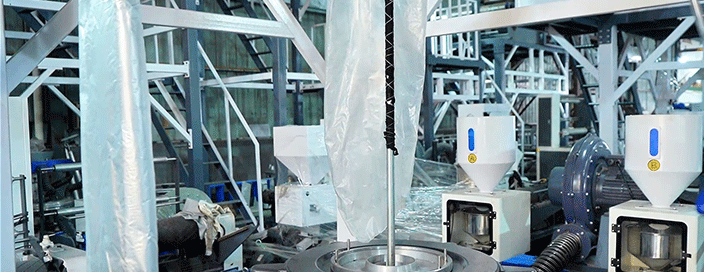

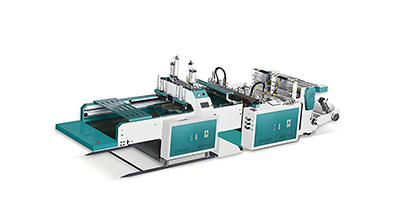

Guoran Printing Machines are for high-performance flexographic and gravure printing, working with diverse film substrates. They enable precise HD printing of logos, barcodes and multi-color patterns, ensuring vibrant colors, sharp details and versatile packaging. With advanced drying systems and precise tension control, they guarantee stable continuous high-speed production. Guoran is your reliable partner for efficient, high-quality packaging printing, maximizing productivity and cutting downtime.

✅ Exceptional Print Quality: Delivers HD printing with overprint error ≤0.1mm, ensuring sharp details and vibrant colors for premium packaging.

✅ High Production Efficiency: Pairs high printing speeds with integrated drying systems and stable tension control for consistent, uninterrupted production.

✅ Wide Material Adaptability: Adapts to various film substrates (covering labels, films, bags) for strong application flexibility.

✅ Operational Stability: Features robust systems and integrated controls for consistent performance and less operational downtime.