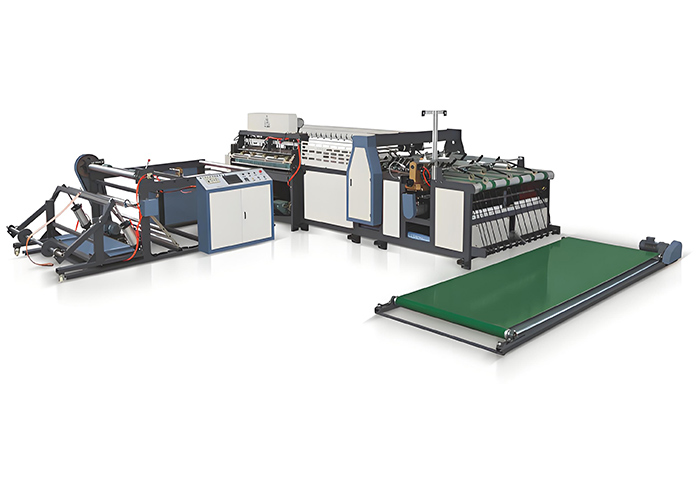

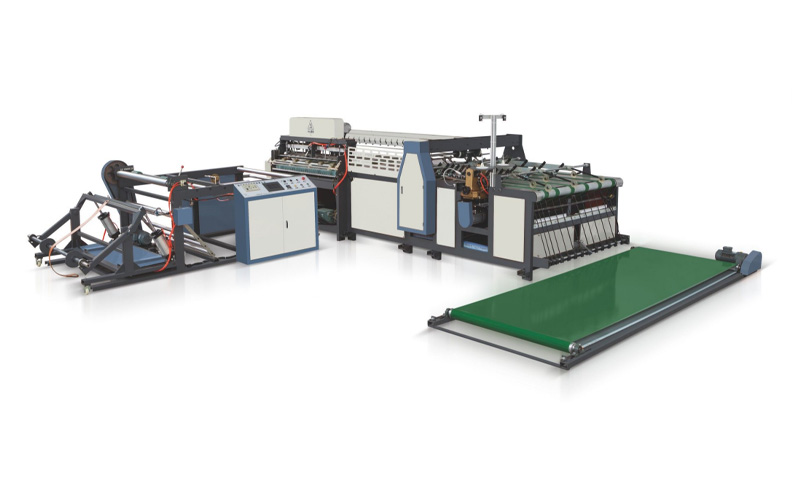

The woven bag making machine is a one-stop fully automatic machine designed for producing high-quality woven bags. It integrates cutting, sewing, and printing processes, providing an efficient solution to replace traditional labor-intensive methods. With advanced technology and stable performance, this equipment ensures standard, neat, and professional woven bag production.

✅ All-in-one design: Combines cutting, sewing, and printing in one machine, saving space and labor.

✅ High efficiency: Production speed up to 45 bags/min, ideal for mass production.

✅ Cost-saving: Reduces labor costs and improves automation in woven bag manufacturing.

✅ Versatile application: Suitable for producing a wide range of woven bags with different sizes.

✅ Stable quality: Ensures neat sealing, firm stitching, and accurate printing.