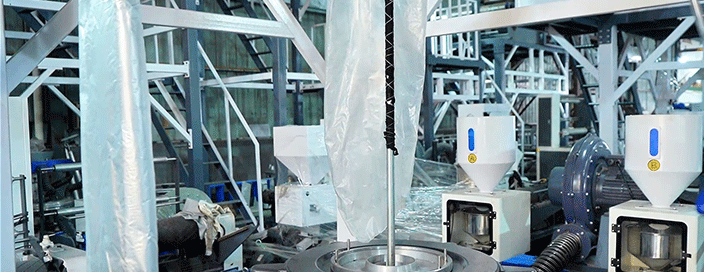

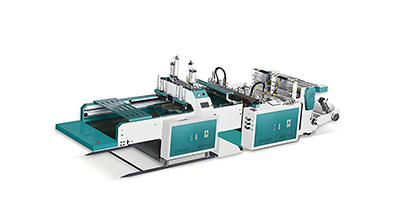

Guoran Zip Lock Film Blowing Machine is specialized in producing high-quality zip lock films, suitable for LDPE, PP, LLDPE. Equipped with precision zipper alignment system and real-time extrusion monitoring module, it ensures stable film thickness and accurate zipper bonding. Crafted in Guoran's advanced China factory, it's a reliable partner for upgrading zip lock packaging production.

✅ Strong Customization: Flexible adjustment of film width (500-2000mm optional), thickness (0.015-0.15mm) and zipper specs.

✅ High Sealing Performance: Produces a precise and durable zipper profile, ensuring excellent sealing integrity for bags, which effectively protects contents from moisture and contamination.

✅ Intelligent Control: PLC system monitors temperature/speed/thickness in real time, auto-adjusts for high qualification rate.

✅ Wide Material Adaptability: Supports LDPE/PP/LLDPE, producing films with high transparency, toughness, etc.