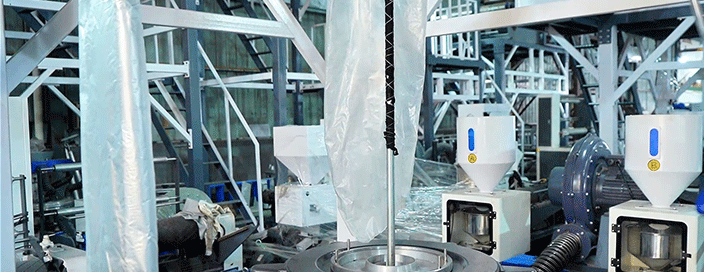

Our fully biodegradable film blowing machine is designed for producing eco-friendly packaging films using materials such as PLA, PBAT, HDPE, and LLDPE. With advanced screw and barrel design, the machine ensures high efficiency, stability, and excellent film quality. It is your reliable partner for sustainable film production.

✅ Simple operation: Robust structure, easy to operate, convenient to maintain.

✅ Eco-friendly production: Supports biodegradable raw materials, suitable for food packaging and sustainable applications.

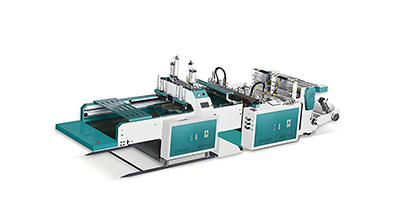

✅ Wide range of applications: Can produce packing films, shopping bags, garbage bags, clothing packaging, vest bags, and more.

✅ High efficiency: Precision-engineered screw design improves plasticization and film uniformity, enhancing output stability.

✅ Flexible film options: Adjustable film width (100–550 mm) and thickness (0.01–0.25 mm) to meet diverse production needs.

✅ Energy saving: Equipped with efficient motors and power system to reduce energy consumption.