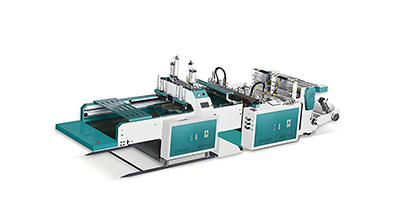

The Gravure Printing Machine is a cost-effective and reliable solution for high-quality gravure printing on flexible packaging materials. It offers smooth operation, high precision, and flexible configuration options to meet different printing needs.

✅ High printing quality: Suitable for films, laminates, and paper, ensuring clear and stable print results.

✅ Stable performance: Horizontal and vertical adjustment of printing cylinders for precise alignment.

✅ Flexible options: Can be configured with auto tension control, corona treater, back printing, and rubber roller pressure pressing.

✅ User-friendly: Simple structure, reliable control system, and convenient operation.

✅ Durability: Heavy-duty frame with long service life, designed for continuous industrial use.