Plastic bags are everywhere — from the grocery checkout to industrial warehouses — yet many of us may not fully appreciate their variety, how they’re made, the materials that go into them, or how to choose the right one for a given application. This article will walk you through these aspects step by step — what plastic bags are, how they are made, common materials, the types you’ll encounter, factors to consider when choosing them, and a conclusion with FAQs. We’ll also highlight how a specialist machine, the Guoran Plastic Bag Making Machine, fits into the manufacturing picture.

What are Plastic Bags?

Plastic bags are flexible packaging products made from polymer materials, designed to store, transport, or protect items. Their versatility lies in their ability to be tailored to different thicknesses, sizes, and functionalities: for example, thin, lightweight bags for retail use, durable ones for industrial parts, or moisture-resistant options for food packaging. Beyond convenience, modern plastic bags also embrace sustainability, with biodegradable variants emerging to reduce environmental impact.

How Plastic Bags Are Made?

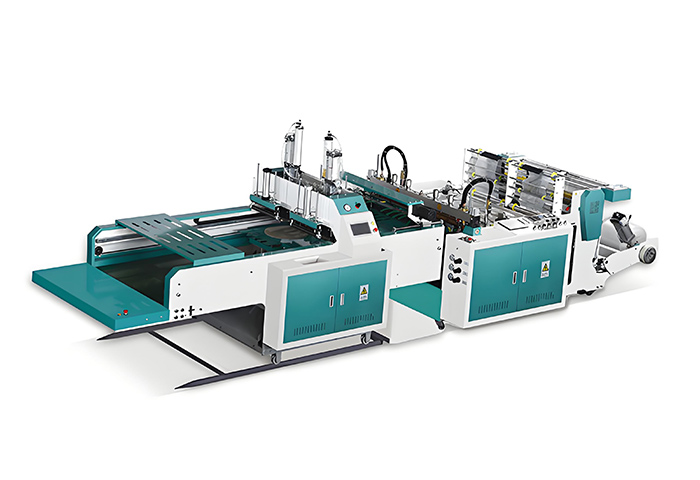

The production of plastic bags relies on precise, automated machinery to ensure consistency, efficiency, and quality—and Guoran Plastic Bag Making Machine is a leader in this field. The core manufacturing process, powered by Guoran’s technology, unfolds in several key steps:

1. Material Unwinding & Feeding: Flexible plastic films (such as PE, PP, or PLA) are loaded onto the machine, where an auto loader (an optional accessory for Guoran machines) ensures continuous, stable feeding. Guoran’s servo-driven feeding system eliminates material waste by maintaining uniform tension, a critical factor for consistent bag quality.

2. Sealing & Cutting: Using advanced servo control and photoelectric tracking systems, Guoran machines achieve ±0.1mm high-precision cutting—ensuring every bag has neat edges and accurate dimensions. For specific needs, the machine can be equipped with double-layer heat sealing cold cutting technology (e.g., Guoran’s GR-600-1500 model) for thicker films (up to 0.10mm) or D-cut bottom sealing (e.g., GT500*2 model) for carrier bags.

3. Stacking & Post-Processing: After cutting, the machine automatically stacks finished bags. Optional modules like the GT-A1300 Horizontal Slitting Machine or JL-8T Hydraulic Punching Machine allow for customizations (e.g., adding handle holes for T-shirt bags or notches for easy tearing).

4. Quality Assurance: Guoran’s rigorous testing ensures reliability: every machine undergoes a 120-hour factory test (48 hours of no-load operation for precision checks and 72 hours of full-load production for stability) before delivery. On-site, Guoran provides 24-hour continuous production verification using the customer’s specified materials, plus operator training—guaranteeing seamless deployment.

What sets Guoran apart is its intelligent automation: a 7-inch touchscreen + PLC control system supports remote operation and maintenance monitoring, while fully automated feeding/punching/rewinding reduces labor by 50%. For high-volume needs, its Twin Channel Vest Bag Making Machine reaches speeds of 800 pcs/min—a game-changer for large-scale retail or packaging facilities.

Common Materials Used in Plastic Bag Production

Choosing the right material influences cost, performance (strength, clarity, barrier properties) and suitability. Some of the commonly used plastics include:

-

Low-Density Polyethylene (LDPE) – a flexible, low-density plastic film with relatively low melting point, good for heat-sealing, moderate strength, good clarity.

-

High-Density Polyethylene (HDPE) – more linear structure, higher density, stronger, more resistant to puncture or tearing, often used for heavier duty bags.

-

Linear Low-Density Polyethylene (LLDPE) – offers a balance: more strength/puncture resistance than LDPE, while still flexible.

-

Polypropylene (PP) – higher clarity, better heat and chemical resistance than many PE types, suitable when transparency and barrier properties matter.

-

Other materials / bioplastics – increasingly, biodegradable or compostable films (e.g., PLA, PBAT) or composite/multilayer films are used to meet more demanding barrier or sustainability requirements.

Types of Plastic Bags

Plastic bags come in many shapes, sizes and functionalities. Below are several common types and how they’re used:

-

Flat Poly Bags – Simple two-side sealed flat bags, ideal for lightweight items like clothing, electronics, small hardware.

-

Gusseted Poly Bags – Bags with pleats/folds (on the sides or bottom) that allow expansion when filled with bulkier or irregular items.

-

Resealable / Zip-lock Bags – Bags with a zip/slider closure allowing repeated opening/closing (good for reuse, convenience).

-

T-Shirt Style Bags / Hand-hole Bags – Common retail shopping bags with handle holes (or shape like a T-shirt) made of thin film, convenient for carrying.

-

Roll Bags / Flat Bags on Roll – Bags supplied on rolls (often perforated) for high-volume dispensing/packaging lines.

-

Heavy-Duty / Industrial Bags – Thicker gauge films, stronger resins (e.g., HDPE or LLDPE) for heavy items, sharp edges or industrial environments.

-

Stand-Up Pouches / Laminated Bags – For packaging food, pet food, snacks: usually multi-layer films or composite structures with barrier properties, sometimes reclosable.

Factors to Consider When Choosing Plastic Bags

Selecting the right plastic bag requires aligning its properties with your specific needs. Here are key factors to evaluate—many of which Guoran’s machines address through customization:

1. Intended Use: For food packaging, prioritize food-grade materials (e.g., PE) and moisture resistance; for heavy items (e.g., industrial parts), choose thicker films.

2. Environmental Impact: Opt for biodegradable bags (PLA/PBAT) if sustainability is a goal—Guoran’s machines are specially calibrated to process these eco-friendly materials.

3. Size & Customization: Ensure the bag fits your products: Guoran offers bag widths from 100mm to 850mm and lengths from 260mm to 1500mm, with customizable molds for unique sizes. Add-ons like printing, punching, or folding are also available.

4. Production Efficiency: For high-volume needs, Guoran’s high-speed models (e.g., 800 pcs/min vest bag machine) and energy-saving design (15-30% power reduction) lower costs and boost output.

5. Durability: For reusable or heavy-duty applications, select PP or thick PE films. Guoran’s servo tension control ensures consistent sealing, preventing bag breaks.

Conclusion

Plastic bags remain one of the most widely used forms of packaging thanks to their flexibility, light weight, cost-effectiveness and the wide variety of forms they can take. Understanding what plastic bags are, how they are made, what materials are used, the different types available, and the factors you must evaluate will help you make better packaging decisions. Meanwhile, the manufacturing side continues to advance — as shown by machines like the Guoran Plastic Bag Making Machine, which allows high efficiency, customization and supports multiple bag types and materials — enabling producers to meet diverse market needs.

FAQ

Q1. What is the difference between LDPE, HDPE and PP bags?

-

LDPE: flexible, lightweight, good clarity, lower puncture resistance.

-

HDPE: stronger, more rigid, better for heavy or sharp items, more puncture-resistant.

-

PP: higher clarity, better heat/chemical resistance, used when visual presentation or barrier is important.

Q2. What is Guoran’s main plastic bag making machine?

Guoran’s core model is the Twin Channel Vest Bag Making Machine, which can produce up to 800 bags per minute—ideal for large-scale vest bag production (e.g., retail grocery bags).

Q3. What types of bags can Guoran’s machines make?

Guoran machines produce vest bags, flat bags, garbage bags, zip-lock bags, D-cut carrier bags, courier bags, and biodegradable bags (20+ types total). Optional features include punching, folding, and printing.

Q4. What is the size range of bags made by Guoran’s machines?

Bag widths range from 100mm to 850mm, and lengths from 260mm to 1500mm. Custom molds are available for unique size requirements.