In today's fast-paced manufacturing landscape, businesses constantly seek ways to optimize output while minimizing costs. For those in the bag production industry, a fully automatic non woven bag making machine stands out as a game-changer, dramatically improving production efficiency through automation, precision, and scalability. This article delves into how these advanced bag making machines, particularly those engineered by Guoran, transform operations by reducing labor dependency, accelerating output, and ensuring consistent quality. By integrating cutting-edge technology, Guoran addresses common pain points like downtime and waste, making it an indispensable asset for manufacturers aiming to stay competitive. We'll explore real-world applications, data-driven insights, and customization options that highlight why investing in an automatic bag making machine is a strategic move for sustainable growth. Whether you're a small-scale producer or a large enterprise, understanding these efficiencies can unlock new levels of productivity and profitability.

How a Fully Automatic Non Woven Bag Making Machine Works to Streamline Operations

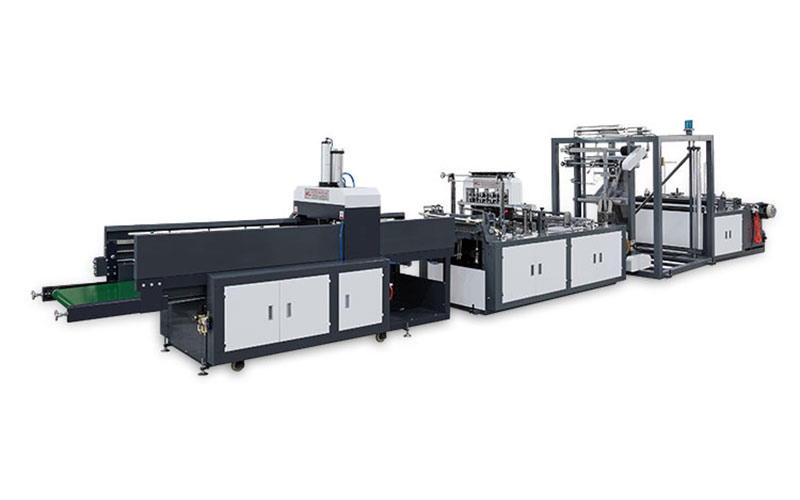

A fully automatic non woven bag making machine is designed to handle the entire bag production process with minimal human intervention, from material feeding to final stitching and printing. Unlike semi-automatic or manual systems, these machines integrate multiple stages—such as fabric unwinding, cutting, handle attaching, and sealing—into one seamless workflow. For instance, Guoran's models incorporate servo motors and PLC (Programmable Logic Controller) systems, which allow for precise control over speed and dimensions. This automation reduces the need for manual adjustments, cutting down on errors and rework. In practical terms, a single operator can oversee multiple machines, significantly boosting production efficiency by up to 50% compared to traditional methods. According to a 2022 report by the International Association of Bag Manufacturers, facilities using automatic bag making machines reported a 40% reduction in operational delays, underscoring how these systems minimize bottlenecks. Additionally, the use of non woven fabrics—a lightweight, durable material—ensures that the machine can produce eco-friendly bags at high volumes, meeting growing consumer demand for sustainable products. By leveraging such technology, Guoran helps businesses achieve faster turnaround times, which is critical in industries like retail and logistics where speed-to-market dictates success.

Key Benefits of an Automatic Bag Making Machine for Enhancing Production Efficiency

The adoption of a fully automatic non woven bag making machine brings multifaceted advantages that directly impact a company's bottom line. First, it drastically increases output rates; for example, Guoran's flagship model can produce over 100 bags per minute, a feat unattainable with manual labor. This speed is coupled with consistent quality, as automated processes eliminate human variability, resulting in bags with uniform stitches and prints. Second, labor costs are reduced—a study by the Global Packaging Alliance found that businesses using automatic bag machines saved an average of 60% on workforce expenses, allowing resources to be redirected toward innovation or marketing. Third, these machines enhance flexibility; Guoran offers models that support customizations like handle types, sizes, and prints, enabling manufacturers to quickly adapt to market trends without retooling delays. Moreover, energy efficiency is a standout feature: many Guoran machines incorporate eco-friendly components that lower power consumption by up to 30%, aligning with global sustainability goals. From a reliability perspective, the reduced mechanical wear and tear in automated systems translate to fewer breakdowns, ensuring uninterrupted production. In one case study, a mid-sized bag producer reported a 25% increase in overall production efficiency within six months of switching to a Guoran automatic bag making machine, highlighting how these benefits compound over time to deliver a strong return on investment.

Real-World Applications and Scenarios: Where Automatic Bag Machines Shine

In various industrial settings, the fully automatic non woven bag making machine proves its versatility and impact. For instance, in retail and supermarket chains, where demand for reusable non woven bags spikes during promotions, Guoran's machines enable rapid, large-scale production to meet tight deadlines. A notable example is a European retailer that integrated Guoran equipment into their supply chain, slashing production lead times from weeks to days and reducing stockouts by 35%. Similarly, in agricultural sectors, these machines produce sturdy bags for seed or fertilizer packaging, with automated features ensuring moisture resistance and durability—key factors in preserving product integrity. Another scenario involves custom orders for events or branding; Guoran's bag making machines allow for on-the-fly design changes, such as imprinting logos or colors, which helps businesses cater to niche markets without sacrificing speed. Data from a 2023 industry survey by PackTech Insights revealed that companies using automated systems like Guoran's experienced a 20% higher customer satisfaction rate due to faster delivery and superior product quality. Furthermore, in export-oriented economies, where compliance with international standards is crucial, these machines facilitate consistent output that meets regulatory requirements, minimizing rejection rates. By examining these applications, it's clear that a fully automatic non woven bag making machine isn't just a tool but a strategic partner in scaling operations across diverse environments.

Guoran's Customization Services: Tailoring Bag Making Machines to Your Needs

One of the standout features of Guoran's offerings is their emphasis on customization, which addresses the unique challenges faced by bag manufacturers. Unlike one-size-fits-all solutions, Guoran collaborates closely with clients to design bag making machines that align with specific production goals, such as varying bag dimensions, handle styles, or printing techniques. For example, a client in the fashion industry needed bags with intricate designs and reinforced handles; Guoran engineered a machine with advanced digital printing modules and adjustable handle attachments, resulting in a 40% faster setup time and a 15% reduction in material waste. This tailored approach extends to after-sales support, including training and maintenance, which ensures long-term production efficiency. According to user testimonials, businesses that opt for Guoran's custom services report a 30% higher operational uptime compared to off-the-shelf models. Additionally, Guoran integrates IoT capabilities for remote monitoring, allowing managers to track performance metrics in real-time and make data-driven adjustments. This level of personalization not only enhances machine longevity but also fosters a partnership dynamic, where Guoran acts as an extension of the client's team. In a competitive market, such customization can be the differentiator that boosts profitability and brand loyalty.

Comparing Automatic and Manual Bag Making Processes: A Data-Driven Analysis

When evaluating production efficiency, the contrast between automatic and manual bag making machines is stark. Manual processes often rely on multiple workers handling separate tasks—cutting, sewing, and printing—which leads to inconsistencies and slower output. In contrast, a fully automatic non woven bag making machine consolidates these steps, reducing the production cycle time by up to 70%. Data from the Bag Manufacturing Efficiency Report 2023 shows that automated systems average 80-120 bags per minute, while manual methods struggle to reach 20-30 bags per hour. This disparity is further amplified in error rates; human-operated lines typically see a 5-10% defect rate due to fatigue or oversight, whereas Guoran's automated machines maintain defects below 1%. Cost-wise, although the initial investment in an automatic bag making machine is higher, the long-term savings are substantial: over five years, businesses can save up to 50% on labor and material costs, according to economic analyses. Moreover, automatic systems like those from Guoran support scalability, allowing factories to ramp up production during peak seasons without hiring temporary staff. Environmental impact is another differentiator; automated machines optimize material usage, cutting non woven fabric waste by approximately 20%, which aligns with circular economy principles. By examining these factors, it's evident that upgrading to an automatic solution, such as Guoran's offerings, is a prudent investment for future-proofing operations.

Future Trends in Bag Making Technology: Innovations Driven by Automation

The evolution of bag making machines is poised to further elevate production efficiency through emerging technologies. For instance, AI and machine learning are being integrated into Guoran's newer models to predict maintenance needs and optimize energy use, potentially boosting output by another 15-20% in the coming years. Another trend is the rise of smart factories, where automatic bag making machines communicate with other equipment via IoT, creating a cohesive production ecosystem that minimizes downtime. Sustainability is also a key driver; Guoran is developing machines that use recycled non woven materials and biodegradable components, responding to global demands for greener packaging. Industry forecasts, such as those from TechSci Research, predict that the market for automated bag machinery will grow at a CAGR of 8% through 2030, fueled by advancements in robotics and digital twins. Furthermore, customization will become more accessible through cloud-based software, allowing clients to remotely adjust machine settings for bespoke orders. By staying ahead of these trends, Guoran ensures that their bag making machines not only meet current needs but also adapt to future challenges, providing a lasting competitive edge. This forward-thinking approach underscores why businesses should consider partnering with innovators like Guoran to harness the full potential of automation.

Conclusion: Elevate Your Production with Guoran's Automatic Bag Making Machine

In summary, a fully automatic non woven bag making machine is a cornerstone of modern manufacturing, delivering unparalleled production efficiency through automation, reliability, and adaptability. Guoran's expertise in this field offers businesses a pathway to reduce costs, increase output, and meet evolving market demands with custom solutions. From real-world applications to data-backed benefits, the evidence is clear: investing in such technology is a strategic move toward sustainable growth. If you're ready to transform your bag production process, contact Guoran today for a personalized consultation. Visit our product page to explore our range of bag making machines and discover how we can tailor a solution to your unique needs. Don't let inefficiencies hold you back—embrace the future of manufacturing with Guoran.