For beginners looking to enter the non-woven bag production industry, understanding the basics of the key equipment is a critical first step. It helps avoid confusion when planning production or evaluating options later. This article breaks down essential points to clear up common doubts about these machines.

What Is a Non-Woven Bag Making Machine?

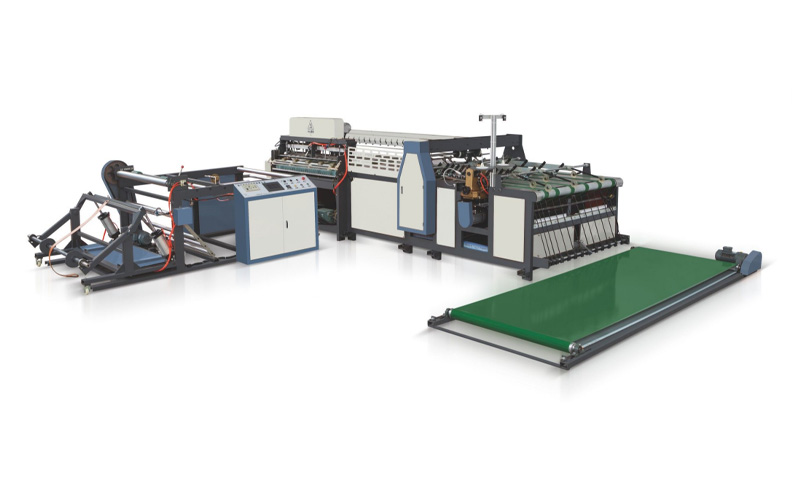

A Non-Woven Bag Making Machine is specialized equipment designed to process non-woven fabrics into finished non-woven bags. Unlike machines that make plastic bags, it focuses on materials like spunbond or meltblown non-wovens—materials known for being lightweight, durable, and often reusable. Importantly, this machine does not produce non-woven fabric itself; it takes pre-made non-woven rolls and transforms them into functional bags.

What Are the Basic Working Steps of This Machine?

The operation of a Non-Woven Bag Making Machine follows a straightforward, sequential process that even beginners can grasp:

1.Fabric Unwinding: The machine first feeds a roll of non-woven fabric into the system, ensuring the material stays flat and aligned to avoid wrinkles in the final product.

2.Bag Shaping: Next, the fabric is folded and formed into the basic structure of a bag—this step determines whether the end product is a tote, flat bag, or another common style.

3.Sealing: Heat or ultrasonic technology is used to seal the edges of the shaped fabric. This creates strong, leak-proof (if needed) seams that hold the bag together.

4.Cutting: Finally, the sealed fabric is cut into individual bags. Some machines also add extras like handles or printing at this stage, but these are optional upgrades.

What Key Factors Should Beginners Pay Attention to When Understanding the Machine?

Beginners often overlook small but important details that affect how well the machine fits their needs. Here are two key points to focus on:

•Fabric Compatibility: Not all Non-Woven Bag Making Machines work with every type of non-woven fabric. Some are optimized for thinner fabrics (used for light-duty bags like shopping totes), while others handle thicker, sturdier fabrics (for reusable grocery bags). Always check which fabrics a machine supports before evaluating it.

•Speed vs. Bag Type: A machine's production speed (how many bags it makes per minute) depends on the bag style. For example, simple flat bags are produced faster than bags with handles or complex shapes. Speed should not be the only metric—match it to the specific bags you plan to make.

What Are Common Misconceptions About Non-Woven Bag Making Machines?

Clearing up myths helps beginners avoid bad decisions. Here are two frequent misunderstandings:

•Myth 1: It can make any non-woven product. Truth: These machines are designed only for bags. They cannot produce other non-woven items like face masks, tablecloths, or industrial wipes—those require different specialized equipment.

•Myth 2: It needs a highly skilled operator. Truth: Modern Non-Woven Bag Making Machines come with user-friendly controls. Most beginners can learn basic operations with a few hours of training, though more complex tasks (like adjusting for new bag styles) may take more practice.

Conclusion

Understanding the basics of Non-Woven Bag Making Machines—what they are, how they work, key factors to consider, and common myths—sets beginners up for success. It helps you ask the right questions when researching equipment and ensures your production plans are realistic.

If you want to learn more about how Non-Woven Bag Making Machines can align with your specific production goals, or explore equipment details that match different fabric types and bag styles, you can visit our product page for in-depth information tailored to industry needs.