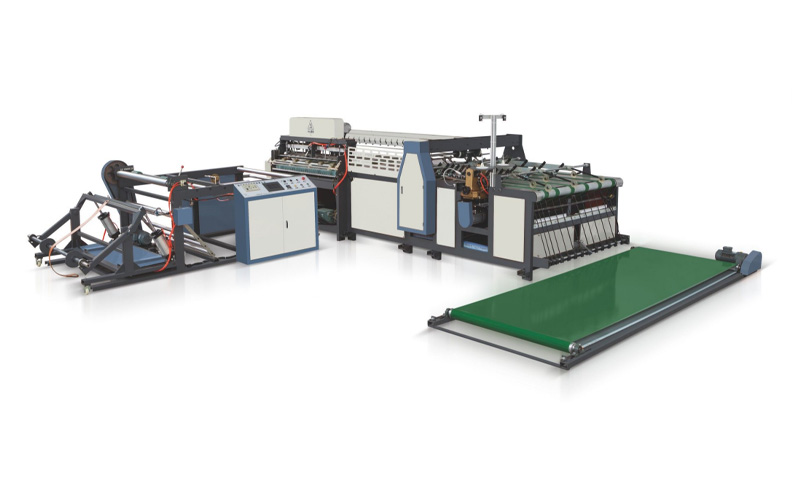

Fully Automatic Woven Bag Cutting, Sewing And Printing All-in-one Machine

Bag Width:450-800mm

Bag Length:550-1300mm

Substrate Specifications:∅1100x1200mm

Production Speed:23-45Bag/min

Bag Width:450-800mm

Bag Length:550-1300mm

Substrate Specifications:∅1100x1200mm

Production Speed:23-45Bag/min

The production process fully achieves humanized service.lt can completely replace the previous heavy physical labor. The process is divided into rolling up - cutting -folding - sewing the bottom - printing-bag collection.

Automatically complete the fixed-length thermal curling and bottom sewing of color-printed or blank woven tube cloth, saving labor.

Adopt touch screen setting, PLC control, servo motor drive, and accurately control the bag length.

After thermal cutting, the bag is smoke-free and non-sticky, and easy to open.

The printing machine automatically matches the sewing speed, no need to change the plate roller, and the plate can be easily changed for short orders.

The printing operation is simple, the start is soft, and the color registration is accurate.

The combination of anilox roller and ink roller transfers ink,the ink color is uniform, ink is saved, and the printing finish is enhanced.

Automatic counting, bags can be fed in stacks, and single-person operation saves labor.

| Name | Unit | Parameter | Remark |

| Working Speed | Bag/min | 23-45 | Depends on the sewing machine speed (2000r/min), needle pitch and bag width |

| Bag Width | mm | 450-800 | Same size for full page printing |

| Bag Length | mm | 550-1300 | 550-1200 for full page printing |

| Cutting Accuracy | mm | ±2 | Color count and reverse printing can be customized |

| Printing Color Number | Colors | Positive Two Colors | |

| Substrate Specifications | mm | ∅1100x1200 | max |

| Substrate Weight | Kg | 500 | max |

| Folding Width | mm | 20-40 | With single and double folding former |

| Automatic Deviation Correction | mm | 130 | |

| Line Breakage Shutdown | Automatic Detection | ||

| Material Stack Quantity | Bag | 1-100 | Can be set by yourself |

| Machine Input Voltage | V | 380 | According to customer needs |

| Bag Cutting Method | Electric Cutting | Hot Cutting Smokeless Knife | Customizable cold cutting |

| Material Collection Method | Carbon Rod Slapping | Electric flapping and collecting | |

| Machine Power | KW | 15 | Operating power: 12KW |

| Machine Weight | T | 2.5 | |

| Machine Appearance | m | 9x5x1.7 | LxWxH |

Bag Width:450-800mm

Bag Length:550-1300mm

Substrate Specifications:∅1100x1200mm

Production Speed:23-60Bag/min

Bag Width:200mm-600mm

Bag Length:200mm-999mm

Thickness:18-90g

Production Speed:50-120pcs/min