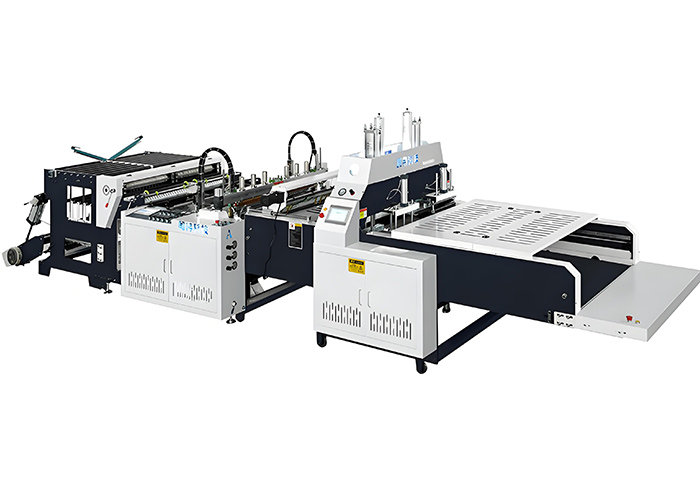

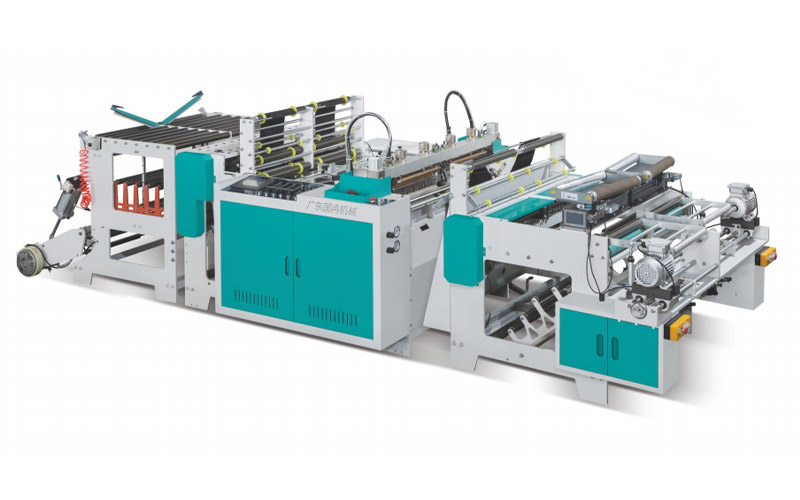

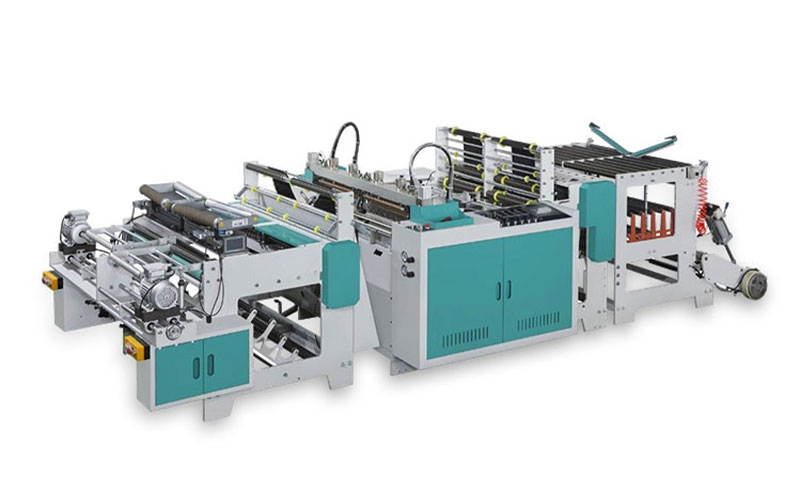

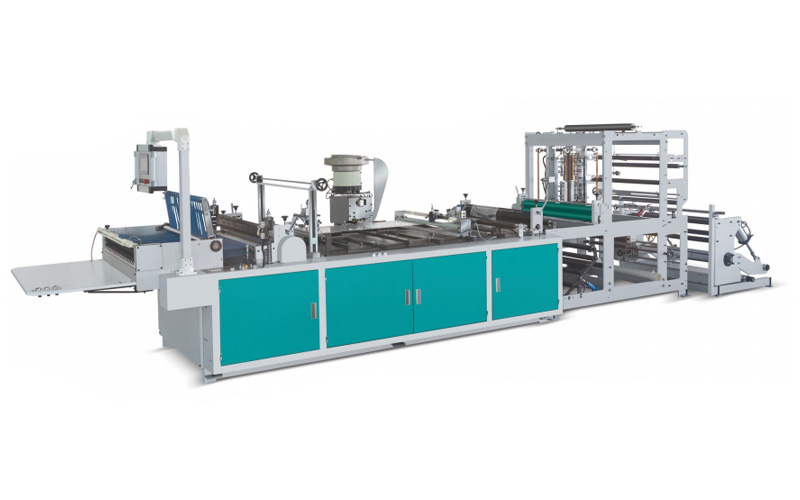

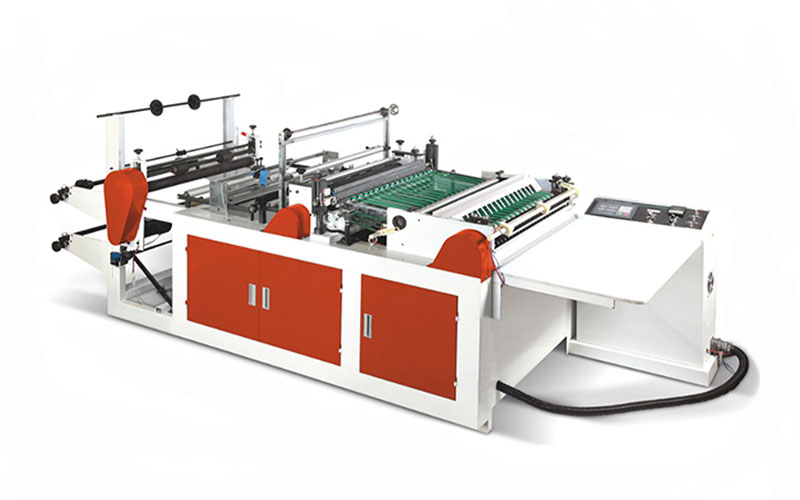

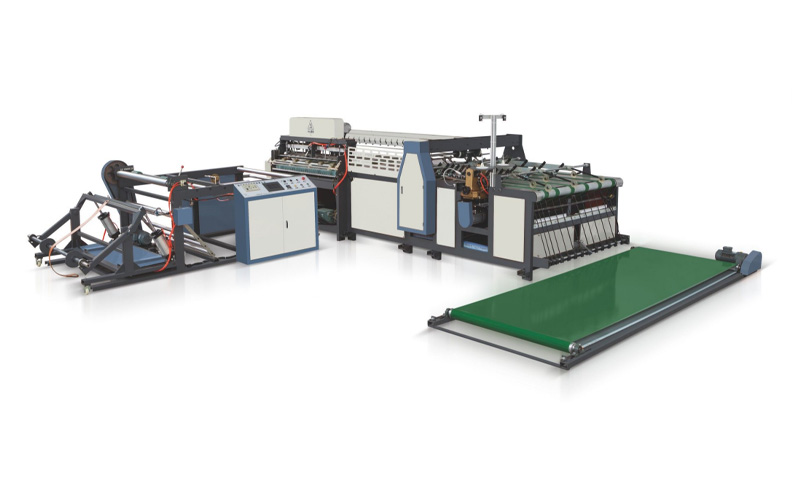

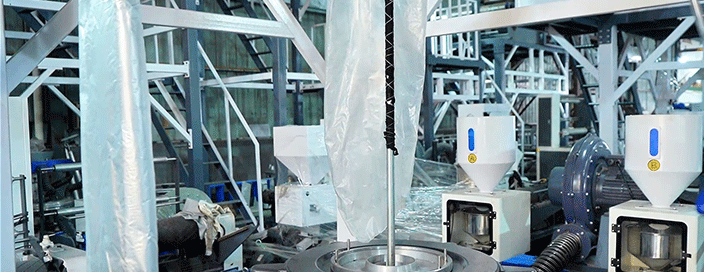

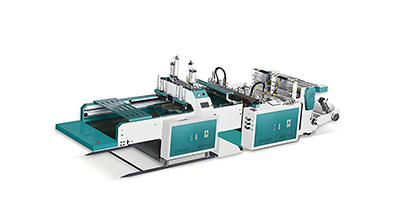

Guoran plastic bag making machines process PE, PP, PLA, and other flexible films into various bags with high-precision sealing, cutting, and stacking. Widely used in food packaging, retail, medical, and industrial fields, Guoran offers models such as the T-shirt Bag Making Machine for supermarket bags, the Roll Bag Making Machine and the Biodegradable Bag Making Machine, ensuring stable and eco-friendly production.

✅ Excellent Equipment: Guoran machines feature Touch Screen + PLC control with remote monitoring for easy operation and reduced failure rates. Designed for higher speeds and greater automation, they help cut labor costs significantly.

✅ Optimized for Efficiency: Built for energy saving and high material utilization, Guoran machines lower long-term production costs through optimized performance.

✅ Warranty Service: Guoran provides lifetime remote technical support, a global after-sales network, and reliable long-term spare parts supply.